Stop under-sink leaks with this 30-minute f

Even if you spend time rebuilding the old valve, the issues will eventually come back. The best way to handle defective valves is to swap them out for contemporary quarter-turn ball valves. They rarely break down, leak, or wear out, and best of all, installation only takes about an hour. Heres how to put them in.

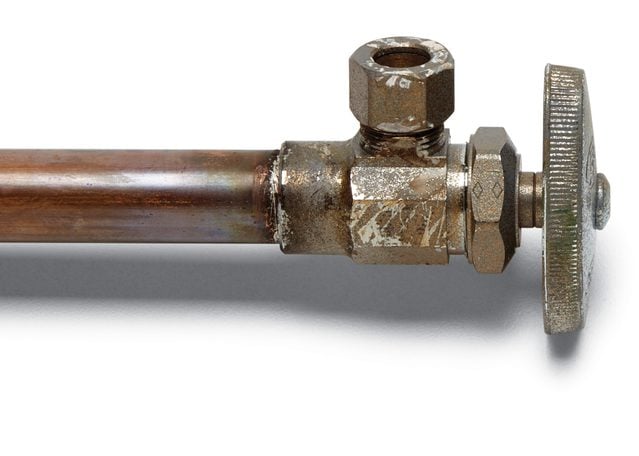

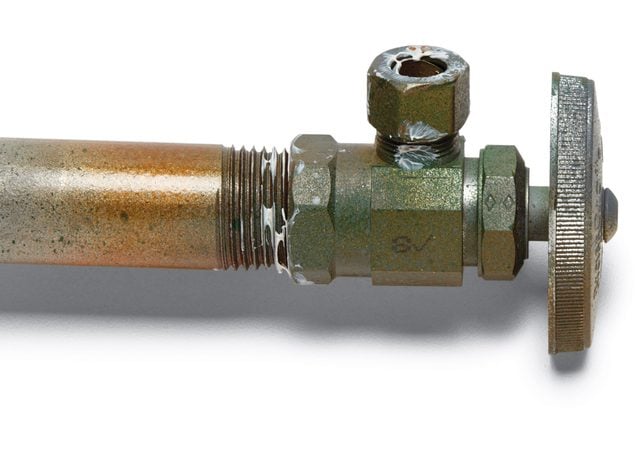

One of two methods connects a shutoff valve to copper plumbing pipes:

Referring to the photos below, determine the type of connection that is present in your home.

We advise hiring a plumber to replace your galvanized pipes if you live in an older home. Changing the valve may seem as simple as unscrewing the old one. However, if the threads are rotted or the pipe is internally rusted, this “simple” plumbing job could become a plumbing nightmare. These guidelines won’t apply if your home is plumbed with PEX or plastic pipe.

Buy a quarter-turn shutoff ball valve to match the size of the incoming copper pipe and the supply tube connection once you’ve determined the type of connection. A torch, flux, solder, emery cloth, wire brushes, and a flame protection cloth to protect the wall are required if you’re replacing a sweat valve. A corroded escutcheon (wall trim plate) and an outdated supply tube are also good candidates for replacement at this time. I hate to break your bubble, but you must immediately stop believing these 10 plumbing myths!

Sweat Valve:

There are no hex flats on a sweat shutoff valve where copper tubing enters from the wall. Swap out a sweat valve for a compression valve or another sweat valve. Step 2.

Sign Up For Our Newsletter Step 3

In the area where the steel pipe enters the valve, look for threads and hex flats. Step 4.

Shut off the water at the main shutoff valve. Turn your gas water heater’s knob to the “pilot” position if you have one. Shut off the circuit breakers to an electric water heater. Then, to drain the pipes, open a faucet on the ground floor of your home and another faucet on a higher level. Then disconnect the supply tube from the shutoff valve. Replace the valve. Step 5.

Close the new valve. then let the water run until all of the air is removed from the pipes by opening the water main shutoff valve. Then shut off the upper and lower faucets. Check the new valves for leaks. Reset the water heater’s gas valve to “on” or turn on the electric water heater’s circuit breakers. Step 6.

Using pliers to hold the valve, remove the packing nut and the entire valve stem. If the old washer is still adhered to the seat, peek inside and remove it. The valve stem can be removed to allow any remaining water to drain out and simplify the unsweating procedure. Make sure there is a fire extinguisher nearby before using a torch, and protect the wall with a flame-resistant cloth. Then remove the old valve and the remaining solder.

Start by covering the copper tubing with the flame protection cloth and taping it to the wall. Aim the torch at a small distance and toward the valve body. As soon as the solder melts, use pliers to twist and remove the valve from the copper tubing. Step 7.

Clean the tubing with emery cloth. Sand off all traces of solder if you’re replacing a sweat valve with a compression valve before installing the new escutcheon, nut, and sleeve. If not, remove just enough of the old solder to make room for the new sweat valve to slide onto the tubing. Remove the stem from the new quarter-turn valve, wire-brush the opening, and flux the valve and copper tubing.

Put on a pair of leather gloves and grab a wet cotton rag (microfiber will melt). Heat the valve just enough to draw in the solder while wearing the flame protection cloth. Heat the remaining solder with the torch until it’s molten. When the solder melts, use a damp cloth to remove the extra solder. Be sure to wear leather gloves to prevent steam burns. Step 8.